FOR REDUCING PRESSURE DROP GAPS AMONG ALL STEAM REFORMER TUBES

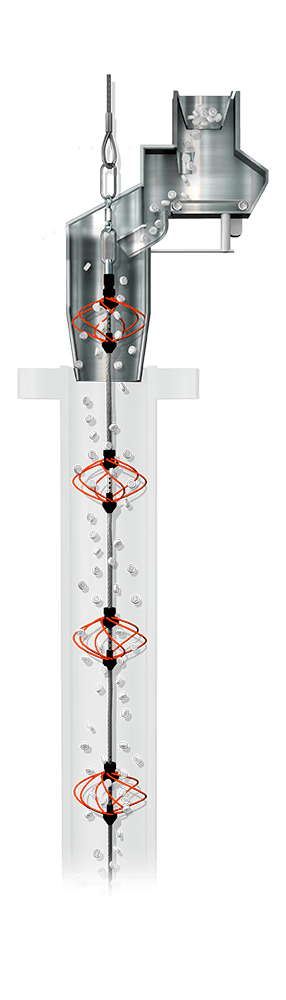

The patented CALYNET® technology assures an easy and fast loading of catalysts used within the steam reforming units.

Automatic technology and non-metalic aparattus avoid atriction and guarantee less than 3% of deviation in 97% minimum of the tubes.

THE REGULAR AND UNIFORM LOADING

This unique solution is applicable to all types of particles and to all sizes of tubes.

The use of soft spiral lines rotating inside the tubes reduces the duration of the maintenance operations and leads to an increase of the catalyst active sites and the highest homogeneity.

CALYNET® technology allows a better productivity along the whole operation of the installation.

The soft feeding system reduces the breaking of catalysts and dust formation.

Stability of pressure drop throughout the tubes is controlled within a deviation below 3% for a minimum of 97% of the tubes.

The constant flowrate guarantees a faster loading and less operators on site.

The soft feeding system greatly reduces the breaking of catalysts and the dust formation.

Stability of pressure drop controlled within a deviation below 3% on 97% minimum of the tubes.

PREMIUM CLASS SERVICES

- Video inspection before start up.

- Optimal loading of tubes.

- Measuring delta P before, during and after loading.

- Report and recommendations.

- Services performed by recognized and highly qualified experts.

ACTIVITIES DEVOTED TO YOUR TECHNOLOGICAL ADVANCEMENT

- A major investment in R&D, to offer our customers innovative technologies and taylor-made services.

- Loading of all types and all brands of catalysts and adsorbents, and all types of units : hydrotreaters, reformers, hydrocrackers, hydrogen production, driers, adsorbers…

- Supervision of loading operations (sock or dense) and supervision and repairs of reactor internals mounting.

- Inspection and expertise (independant for catalyst suppliers and for refiners).

- CREALYST assigns its own operators worldwide in refineries and petrochemical factories.

Documentation

DO YOU HAVE A PROJECT ?

CONTACT US

202 Leghrand Court

League City

Texas 77573

États-Unis

+1 (409) 356 6091