HOMOGENEOUS DENSE LOADING FOR REACTORS IN THE OIL INDUSTRY

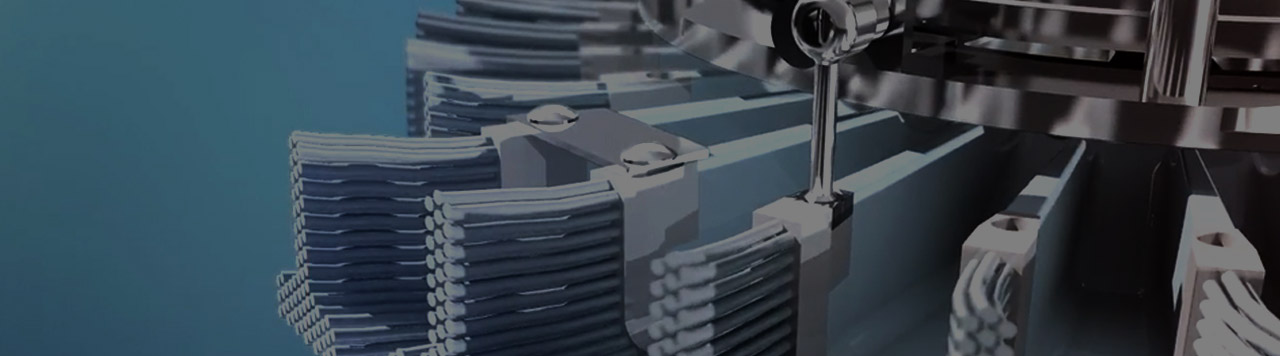

The patented CALYDENS® technology ensures a homogeneous and dense loading of catalyst or adsorbent particles that are uniformly distributed in the reactor.

A SYSTEM THAT MEETS THE HIGHEST DEMANDS OF REFINING PROCESSES

CALYDENS® allows the loading of reactors of any size and diameter. Its flow rate adapts to the on-site configuration to guarantee the flatness of the catalytic bed in the shortest possible time.

The flexible brushes at the outlet ensure a gentle distribution to preserve catalyst integrity, without any dust generated.

Light-weight and easy to carry (5kg to 17kg), CALYDENS® is equipped with a unique system of regulation and homogeneous distribution of the catalyst.

With CALYDENS®, CREALYST-Oil guarantees 97% of the loading representative Laboratory Test Density.

Up to 28% more catalyst by weight in the same volume.

Flat and horizontal catalyst bed.

Dense filling at 300mm under the distribution tray.

PREMIUM CLASS SERVICES

- Guarantee of homogeneous structure of the catalyst bed with a flat top profile.

- Guarantee of dense loading until 300mm under the distribution tray.

- Services performed by recognized and highly qualified experts.

- Compliance with the loading plan ; report and recommendations.

- CALYDENS® can be associated with CALYHAWK® for the measurement of the bed profile.

ACTIVITIES DEVOTED TO YOUR TECHNOLOGICAL ADVANCEMENT

- A major investment in R&D, to offer our customers innovative technologies and taylor-made services.

- Loading of all types and all brands of catalysts and adsorbents, and all types of units : hydrotreaters, reformers, hydrocrackers, hydrogen production, driers, adsorbers…

- Supervision of loading operations (sock or dense) and supervision and repairs of reactor internals mounting.

- Inspection and expertise (independant for catalyst suppliers and for refiners).

- CREALYST assigns its own operators worldwide in refineries and petrochemical factories.

DO YOU HAVE A PROJECT?

CONTACT US

23bis avenue de l’Europe

78400 Chatou

France

+33 (0)1 39 14 83 35